|

|

|

|

|

The following is a document written by Professor Marc Durand of the University of Quebec at Montreal regarding the problems of hydraulic fracturing from the perspective of profitability versue long-term cost to the citizens and the state.

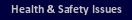

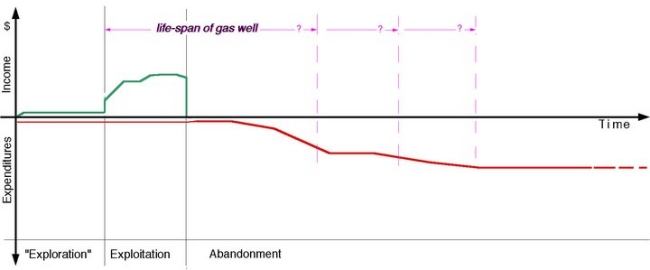

by Shale Gas Info Thursday, March 10, 2011 by Marc Durand, doct-ing en géologie appliquée Professeur retraité, dépt. Sciences de la terre, UQAM Following the publication on the Web of my article on shale gas -Gaz de schiste- quelques réflexions d'un ingénieur en génie géologique, I received numerous comments, one of which was the following question from Claude Paré: "I would like M. Durand to clarify two points. I know he is knowledgeable about cement - what, in his opinion, is the life of these wells; could they become conduits for the liquids and the gases . Can the saline solutions and the fracturing fluids buried underground weaken the cement?" I haven't read all the briefs to BAPE*, but among those I have read there is not one which asks or addressses your question, which I would reformulate thus: "What is the life-span of a well - including its ability to contain the drilling permanently, and what will happen when the underground part of the well loses its integrity through corrosion and other degradations?" There is necessarily an expiry date; this is longer for structures that are inspected and maintained, and shorter for temporary works; all engineers know this fundamental fact; for example the tunnel lining required to stabilize and enclose the vault of a metro tunnel is not the same as a temporary gallery for a mine. In the case of the metro, it must be very solidly and durably constructed; and a program of inspection and upkeep added for the whole duration of its use. We have seen this recently with viaducts and bridges; at the end of their life, and preferably before, they must be demolished and rebuilt. One cannot take a chance of allowing a structure to exceed its lifespan. Certain bridges, well maintained, last for centuries; others, badly suited to their use and exposure, have a life span of only 50 years. For a temporary building, or one which humans do not use, the criteria for security and life span are lower. All that we know about shale gas wells is that these are works designed for a very short life span: the years of the well exploitation. After it has been capped (cemented), the top of the structure is buried and vegetation planted on the site (brief to BAPE*). There is practically nothing published which would respond to Mr Paré's question about the life-span of the subterranean structure. The question is, however, essential. In 20 or 30 years how much will 20,000 depleted wells, which will simply have been concealed before being bequeathed to the geographic locale, cost us per year? There is total silence on this question, because the mining and oil sector has never been concerned for what happens to the drill holes afterwards. The industry has never allocated funds for that. The newest legislation requires only the rehabilitation of the site at the end of its exploitation. Companies must restore the surface of the site but there is almost nothing for what is underneath. There are thousands of well sites at the end of their life span, hidden in the surface vegetation which have become all the more dangerous because their location has been forgotten. In the United States, there are more and more reports of victims of explosions from gas which resurfaces from old wells. In the majority of cases, it is old exploration wells dating from the beginning of the last century (Appalachia, Colorado). The problem will take on a whole new dimension shortly with the end of life of the gas wells situated in layers which have undergone intense modification by hydraulic fracturing. The technique, newly applied on a large scale, will leave thousands of abandoned wells under inhabited zones, without anything being known of the impacts which will arise at the end of the work. Let's be clear about what we understand by the end of the life-span of a shale gas well. A working well has a life of 3-5 years. It is an optimal plan for extracting the gas as quickly as possible at the lowest cost. The output the fractured shale delivers is very high at first, then it diminishes logarithmically or exponentially. The wells are abandoned when the rate of gas is deemed unprofitable; at which point about 20% of the gas in place has been captured. In classic gas reservoirs, up to 95% of the natural gas can be captured. "For shales, recoveries are expected to be around 20% because of low permeabilities despite high-density horizontal drilling and extensive hydraulic fracturing." National Energy Board, A Primer for Understanding Canadian Shale Gas. At the end of this period the extraction well is summarily transformed for another job or task whose sole purpose is to stop the flow of gas in the well. By means of blocking downhole plugs, cement plugs in the tubing, etc., the temporary extraction site must be turned into something permanent, the function of which is very different. In reality, practically nothing changes in the structure and composition of the well but the addition of a permanent plug. Whatever the design of the plug, the new work cannot have a drastically modified life-span. Nevertheless, these plugged wells must resist in perpetuity the pressure of the methane which will continue to seep from the fractured shale. And let's not forget that 80% of the gas remains in the shale at the end of extraction. Underneath the inhabited plain, the Utica will have become an extremely permeable reservoir, still containing the left over methane after the skimming of the 20%. This enormous volume, 100 metres thick times 10,000 Km squared will be directly connected to the surface by 20,000 slowly corroding wells. The steel pipes and the sealing grout in an extremely saline environment will erode. This will possibly vary in speed from one well to another according to the quality of the sealing work done. The life duration of each of these wells, is the time before the deterioration is so advanced that major leaks force the authorities to intervene. From then on there will necessarily be a cost. This cost may appear very early in the process for certain wells, as has happened in Québec with some wells whose exploitation phase hasn't even begun; but for now, the industry is still the owner of the wells and so pays the cost. This demonstrates though, that leaks occur even with brand new wells. Figure 1 shows various routes the gas can take to reach the surface and drinking water wells (P). The light blue letters (A,B,C) show the gas flow in the case where the drilling intersects a flaw or a long fracture. It is difficult to estimate in what proportion of wells this could occur because a detailed geological map is not readily available for the rock under the soft deposits of the St Lawrence Valley.  Figure 1 : possible leaks for an extraction well - capped well Where there is the presence of such a fracture, the injected liquid opens this route and pushes very far (A) into the Lorraine strata. The flow path is opened permanently to continue into the sandstone and other more permeable layers. Gas leaks show up in the artesian wells and the dwellings in proximity to the fault. Note that the fracturing fluid also penetrates a great deal further than the fault in the limestone (A) The Trenton is more permeable than shale and it contains very salty water. Thus a route is opened for saline contamination. Some analyses of fracking water indicate that this type of problem has already been encountered in the first wells. Between the pipes and the drilled rock, and between the producing pipes and the protective sheath, the quality of the placement of the grout can leave spaces : annular fractures may also form during the intensive use of the wells. So that it is a possible origin of gas leaks coming from the wells themselves (E and K). As well as these possibilities of leaks, at the end of the well's life, probably between 2 and 5 decades after the end of operations, more generalized leaks will begin progressively, in growing proportion to the abandoned wells. The first reasons will be: 1) the disintegration of the steels and cements of the seal. 2) the pressure of the gas which builds slowly and surely on the capping. 3) the readjustment of the pressure (more precisely, the state of the constraints) in the fractured rock will slowly readjust, shearing off or deforming locally sections of the pipes. The Utica strata tend to inflate when exposed; the same property in the depths will tend to flow and close up the opened fractures a bit over time. The fractured shale will thus tend to lose some of its permeability; but this will not be sufficient to return it to its initial impermeability. On the contrary, these micro ruptures will contribute to the liberation of yet more methane over time. We are dealing here with structures which will disintegrate in extremely salty environments underground far from all possibility of inspection and maintenance, in rock transformed by the operations of hydraulic fracturing. The flow of fluids, saline water and methane will become modified. All the structures linking the surface of the transformed Utica will sooner or later attain an advanced degree of decomposition. The wells will reach a state where their function as sealing devices will no longer be operational. That means what exactly?: mega-problems at each of the wells, means of mitigation to be put in place, complex studies to be undertaken to try to find a solution, BAPE* commissions for each site? There will be many of the 20,000 , maybe between 250 and 500 new cases per decade in one generation. Billions to plan for in the budget of Québec. If the heads of the wells are kept accessible for perpetuity, rather than restore the surface, one would have a less complex task, because one could sound the ground and know when catastrophe threatens. Yet no one anywhere is proposing that. It is said that the site must be restored at the conclusion of the extraction. All that means is burying and forgetting the problem until it hits us in the face. Finding a solution at that point will be an impossible task, as it is impossible to obliterate a well . The hole remains there, even if one tries to plug it with something else, that other material will never have the same properties as the shale that has been drilled and fractured. This Utica Shale has contained the gas for 400,000,000 years; all our technology, present and future will never manage to do that well. The shale gas industry has established its business plan on the two steps EXPLORATION & EXPLOITATION. In the abandonment period, they are liberated from any cost since the responsability of abandonned wells will be returned to the state; the high cost of curing the problems they created are passed to the next generations. Read my paper: Shale Gas - A Business Plan Very Much in the Red  Figure 2: Business plan with schema of the life-span of the wells Figure 2 above shows revenues and costs for Québec as a whole, that is, the community. The business plan of the gas industry ceases with steps 1 and 2 ; it ends with the halting of the exploitation and the time required to restore the surface. During the first stage (EXPLORATION), the collectivity receives modest annual revenues in the form of exploration permits . For example: 10 cents/hectare +$100/drilled well. Québec, on the other hand, has the costs of analysis, surveillance, inspections, etc. It is certainly a negative balance sheet for the collectivity at this stage. During the exploitation, the surveillance and other costs continue but they are largely compensated for by the fees paid on the extracted gas. At the end of the exploitation, the gas companies cease to pay these taxes. They may also cease to pay the mining rights fees , which would be in their interest. In that case, the full ownership of the gas deposit reverts to the government. The diagram indicates that the life span of these capped structures remains unknown; but we know that it does come to an end. In the current business plan, if one can believe the lessons of the past, it is the collectivity who will assume the costs which will, sooner or later, inevitably appear. The capped wells will not all have the same length of life. For a small number, the deterioration will be apparent soon enough, in the greater mass later, and a last group may miraculously not show any sign of problems for generations. On the whole, the costs may appear early, with an unending increasing curve, mostly near the time which corresponds to the average life-span of the works (figure 2). Whatever the parameters are, the business plan of Gaz-Québec Inc, that is to say, our communal interest in this file, will be strongly one of deficit. Only one winner: the gas companies who have passed us ''un beau sapin'' (a wooden nickel ; literally :a nice fir tree) It is the official name of the well heads (Christmas tree) and that is not a coincidence; it is an omen which tells us to light the lamps while there is yet time... Marc Durand, honorary prof. of engineering geology * Bureau d'audiences publiques sur l'environnement (BAPE) - Québec public inquiry commission on shale gas |