|

|

|

|

|

The following is a document written by Professor Marc Durand of the University of Quebec at Montreal regarding the problems of hydraulic fracturing and why reclamation and remediation of the earth after a natural gas well ceases to produce is not possible.

Foreword : This document is the text complement to a video titled Shale Gas 102 - The EXPERIMENT, availiable for now in its English version: http://www.youtube.com/watch?v=-vMlRc0CSCc or its French version : http://www.youtube.com/watch?v=4Aga9XvQkgs. The text and video discuss the geotechnical aspects of the shale gas industry, more specifically the expected lifespan of the structures in the medium and long term. The EXPERIMENT enlarges upon the previous paper CONVENTIONAL GAS vs HYDROFRACTURING GAS SHALE and the video Shale gas 101-Utica. The English version is also ebedded into this document below.

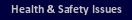

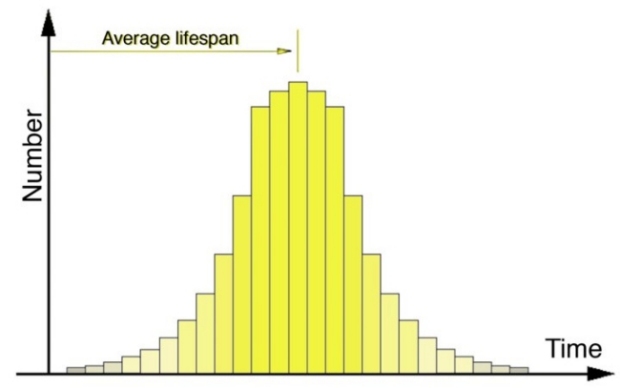

The Longevity of Structures by Marc Durand, doct-ing en géologie appliquée Professeur retraité, dépt. Sciences de la terre, UQAM A really important but little known problem with the exploitation of shale gas is the well's post-exploitation life. This question must be analysed very carefully, for there is an essential element which is of considerable importance in this new industry: this is the fact that hydraulic fracturing initiates the migration of methane in the whole volume of the geologic unit, while only a small amount of this gas is recovered. The extraction takes place over only a few years, but the migration of the gas, once begun by fracturing, continues at least a thousand times longer. The flow is initially very high, but falls fairly quickly below a level deemed profitable for extraction. In a conventional natural gas deposit, that is, one in which the methane has accumulated in natural cavities, it is possible to extract 95% of the gas.* That is because the rock which forms the natural reservoir is very permeable and over the millions of years of a geologic time scale, the gas has had ample time to migrate and accumulate there. It is therefore easy to extract almost in its entirety. This is certainly not the case when one attempts to extract the shale gas which is still dispersed and imprisoned in extremely impermeable rock. Certainly it is possible to create fractures in the shale by means of hydraulic fracturing or other techniques. The result is the same: each of the new fractures constitutes a small zone of great permeability in the shale. The methane and other fluids that are present will migrate towards the fracture. What has taken millions of years in the case of conventional gas deposits, will be reproduced in a tiny fraction of that time, and, as all the new fractures are created at the same time, at first the flow is strong. But it falls off very quickly. More than three quarters of of the methane (80% according to the National Energy Board) (ref.1) remains underground at the end of the exploitation. It will continue to migrate toward the network of fractures and repressurize the wells, after they are closed and abandoned. It is a very different case from the conventional natural gas that we are used to and it begs the essential question: What will happen to the wells after exploitation, considering that enormous quantity of methane seeking a pathway to the surface? By fracturing shale, and with an extraction technique which yields a paltry 20%, we create an enormous, and completely new, problem for ourselves, to which we have presently no solution. How will the wells behave? More precisely, how will the elements behave that were put in place during the short stage of closing and abandoning the wells? In conformity with current practices, the industry spends between 0.1 and 0.3% of the overall cost of the well to seal it. That is very little, and the durability of these closings is pretty much an unknown, as is the rest of the well structure for that matter. A thought experiment: Bury 20,000 propane tanks in a large field. Lets say, at the beginning, each of these containers is 80% full. It is known that these tanks have a limited life span - it is therefore recommended to never fill one that is more than ten years old. Each year a sample is examined in the field and the number of units that have failed is recorded on a graph. At least two criteria may be noted : those which clearly leak a bit and those which are completely corroded, cracked or even exploded (no doubt a small number of the possible ruptures). Let's take the case of the complete ruptures charted on the graph below:  Figure 1 - Average distribution in bell curve of ruptures occurring at the end of the the technical life of a structure, or a civil engineering work. A classic bell curve distribution is obtained. The average life expectancy of the tanks is fourteen years where there are the greatest number of cases. But we notice that out of the 20,000 there are nevertheless ruptures starting at the second year. At the other extreme, a small number last more than 25 years. Note two things: In real life, if someone made that experiment, public security officials would probably intervene after the first explosions. The authorities would close off the field, post prohibition signs, make an intervention study, and finally entrust the "demining" to a specialists who would have to employ costly precautions in order to extract the corroded and dangerous-to-handle tanks. Meanwhile, the madman who created the problem would have taken off for the Bahamas. The exorbitant bill will have to be payed from the public purse. Do you think this experiment is twisted and far-fetched? It is no doubt twisted, but much less so than the one that the gas companies wish to undertake with Québec government support over 10,000 square kilometers of the St Lawrence Valley. Without knowing the life expectancy of the wells , with no evaluation of the long term consequences of their eventual rupture, 20,000 shale gas wells are planned. There is not only the wells to worry about, there will also be 20,000 times the very large block of fractured rock (shown in green in Figure 2). Between 50 and 100 million cubic meters of shale irreversibly modified for each of the 20,000 drillings.  Figure 2 - In bunches of six wells or more, the plan is to extract gas from the whole of the Utica Shale layer: with between 1 and 3 wells per square kilometer the layer's permeability is totally changed. And, in the case of the wells, it is not just a single field which is the site of the experiment, but the the greater part of the St. Lawrence Valley between Montréal and Québec in the ancestral sector containing the lovely villages and landscapes cultivated by preceding generations. Drilling rigs, flares, compressors and trucks are to insert themselves into this landscape. We have an idea of what this radical transformation will produce on the surface: water pollution by the industrial activity, heavy pressure on agricultural and village infrastructure, radical lowering of the quality of life and the land values in the neighbourhood of the industrial structures, etc. But about further underground, we know know very little. This is the reason I call the entire operation AN EXPERIMENT, the title of this text. I say further, that it is an irrational experiment, worse than that of the madman who buried the propane tanks in the field. This is not a small quantity of fuel (4.5 cubic meters of gas per propane tank), but fully 10,000,000 times more, at each drilling site. The only positive difference is that the methane in the rock will escape slowly and progressively, while in the case of the tanks, it is free from the start. On the other hand, it was possible to remove the small propane tanks, but it will never be possible to remove a gas well and the sand blasted fractures in the shale. Let's take a time scale on the order of the life span of the abandoned wells. What is scientifically known, is that the 80% methane left in the shale will continue the geologic process initiated at the time of fracturing. At the end of the exploitation of the well, only 20% has been liberated and extracted. It is no longer profitable to continue to exploit a well after several years because the flow is judged too slow. A well which is sealed reverts to public ownership. That is when the experiment begins, because we enter a completely unknown domain. Nevertheless, the facts at the beginning of the experience are clear enough to predict the outcome with the greatest probability: 1 - The shale still contains 80% of its gas, which continues to be released slowly following an exponential diminution curve. Shrinking curves are published (ref.2) for currently exploited USA shales. 2 - The closed and abandoned wells are sealed deep underground with cement and on the surface with a steel plate. Between the tubing and the drilled rock, porous grout, which was put in place when the well was constructed, serves as a stopper. Even in new wells, the grout outside the tubing has often shown faults, allowing gas to escape in numerous cases. In order to handle these faults, the exploiter has had to perforate the steel tubing in several places in the depths. These breaches will be the parts of the structure which will begin to degrade first. The causes of the the degradation of the wells, and of the leaks and ruptures which ensue, are well known (ref.3) in the case of conventional wells, i.e. those which are simply vertical drillings. These same causes will apply with the new wells , but with greater effect. 3 - In the more critical case of shale gas wells , it is necessary to add the unevaluated effect of drilling horizontally as far as (and perhaps beyond?) 1000m, extending the vertical shaft. What will be the impact on the longevity of steel and grout, (the two principal structural elements of the wells), of having subjected the shale environment to hydraulic fracturing? The shale, formerly watertight, has been rendered a million times more permeable by the fracturing operation; certainly it liberates the gas, but also many other elements that were formerly imprisoned in the rock: radium, high concentrations of mineral elements (the local salinity in the waters of these massifs when they have been found, is eight or ten times that of sea water). All these elements are added to the chemical cocktail of fracturing fluid, most of which remains in the fractured rock. 4 - In the more critical case of shale gas wells, there have also been strong pressure cycles during the fracturing and others during exploitation. This impact on the durability of the steel and grout is certain to further shorten their technical life span. With these four elements, one may already conclude that: Factor 1 will allow the restoration of pressure in the capped wells. The pressure and the quantity of of gas on the seal will increase over the years (ref.4). Factors 2, 3 and 4, indicate that that the wells will slowly but surely degrade. What is the average life span of the well structures, deep under the ground, where, to date, no appropriate studies have been made? This is the unknown element in the equation. We therefore cannot predict when in time we will see the appearance of major leaks for each of the well individually. That is precisely where the great experiment begins.

Figure 3 - The voluntary and involuntary participants in the EXPERIMENT I say that this experiment should not go ahead, and as an engineer, I would absolutely not sign the work plans represented in Figure 2: above all, if 20,000 examples of this type of structure is intended to be placed in an inhabited territory (Figures 2 & 4). There are currently eighteen wells which have been fractured. That is already eighteen too many. There is no technical solution to restore the status quo. Whether we want to or not, we will go through the experiment with these eighteen structures, because they are now there for eternity, - but it is imperative not to add other fracturings. We must also avoid at all costs joining in the business plans concocted by the industry with the government's blessing, and instead, change the arrangements in Figure 3. The most important change is not to authorize the transfer of the property ownership from the gas companies back to the public domain upon the closing of the wells. Those who have built the eighteen wells must remain tied to them for the whole "experiment", that is for a minimum of ninety-nine years, renewable for as long as the methane follows its geological process of migration (that may be a very long time!). I am well aware that very few firms last for centuries, but applying that rule will fix the shale gas problem : no company will launch into another fracturing if they are held responsible. I presented the example of the propane tanks because it is helpful in understanding the question of technical longevity. This also applies to the wells, the structure of the wells , including the capping structure added at the end of exploitation. How long will that "repairjob" hold? is the question that must be asked. The term "repairjob" may seem exaggerated for several experts here, for the methods used are those which are currently used, regulated and which currently constitute the rules of the game. However, as an engineer , I believe that applying the procedures established for conventional gas wells to this new type of well, is indeed a temporary "repair" because it is completely maladapted. To begin with, we have a work conceived and optimized to extract gas (Figure 4A) - the extraction wells with 1000 meters horizontal fracturing. One then attempts, at the end of its useful life, to transform it into a structure for the diametrically opposite function, that is, to contain the remaining gas - the same well and the fracturing of 50 million cubic meters + a cement stopper + a soldered steel plate + some other additives (Figure 4B). This procedure is presently the norm for which the companies habitually spend less than 1% of the total cost of the work. No rules oblige them to do more. No company can be both more virtuous than its competitors and stay in business long . The rules for the closure of intensively fractured horizontal wells in the gas shale are in dire need of rethinking and reformulation.

In Québec law, the plans for drilling and closing of wells do not fall under normal engineering regulations. Thus these works, with the current rules, may be installed without an engineer to approve the plans. I do not know of any engineer who would put his professional reputation on the line to guarantee, on closure, the security for an indefinite number of years of a subterranean reservoir of 50,000,000 m3 of methane with the current drilling plans, of works which moreover, will be uncared for, un-inspected and hidden under a camouflaged surface. We can compare in Figure 4 the millions spent on the extraction structure which has a useful life numbered in years - against the less than 1% of the budget, to add a structure which merely modifies the first in a superficial fashion, while at the same time hoping to modify its function totally and have it last for centuries. But that goes on elsewhere, one may object. But even if elsewhere a madman decided to undertake the experiment with the propane tanks, that does not make it more reasonable to repeat the folly here. No place in the world has yet experienced the "afterward" in the shale gas industry scenario. The United States initiated this industry less than ten years ago; we are still not at the stage when the Experiment really begins. Already though, in the current exploitation period, a strong increase in security problems have been associated with the active well. It will be worse when the are abandoned. Several states in the USA are currently re-examining the situation. Each of the new studies shed new light on this industry which was also launched over hastily there. Each geological context is different, certainly, but to begin this Experiment in an inhabited zone, given the probable results, is completely ill-considered. Marc Durand, doct-ing en géologie appliquée Cited references : 1 - National Energy Board, Nov. 2009, The ABC of Shale Gas in Canada, 23p. 2 - A.Eberman , 2010, Shale Gas - Abundance or Mirage? Why the Marcellus Shale Will Disappoint Expectations, http://www.theoildrum.com/node/7075 3 - Maurice B. Dussault, 2000, Why Oilwells leak:Cement behaviour and Long-Term Consequences,SPE, Porous Media Research Institute, University of Waterloo,Ontario; Malcolm N.Gray, Atomic Energy of Canada Limited,Mississauga,Ontario; and Pawel A. Nawrocki,CANMET,Sudbury, Ontario,SPE International Oil and Gas Conference and Exhibition in China held in Beijing, China, 7-10 November 2000 4 - Durand, M., 2011, Exploitation de puits gaziers classiques vs exploitation par forages à grande extension horizontale et fracturation hydraulique , 25 février 2011 https://www.facebook.com/gazdeschiste2 Shale Gas - A Business Plan Very Much in the Red | |||||||||||||